Finding orientations in disorder

Solid metals typically have their atoms arranged in a highly ordered crystalline structure, aggregated to form a polycrystal. Carbon fibres, on the other hand, are only partially crystalline, and therefore only partially ordered.

When amorphous epoxy is added to carbon fibres to form a composite, the resulting structure is quite distinct from that of a metal. Its complex architecture lacks atomic order: the atoms are not oriented in the same direction. Understanding how each carbon fibre is aligned would allow engineers to tailor the material’s strength and stiffness. This, in turn, could lead to the development of lighter and safer products, such as aircraft components.

Scatterin, a Swedish deep-tech company, has developed software that delivers live diffraction analysis at neutron and synchrotron beamlines, with a focus on metallic materials.

Testing the algorithms at MAX IV

Through the LEAPS-TamaTA access programme for SMEs, Scatterin received beamtime at MAX IV’s DanMAX beamline to get a better understanding of this process.

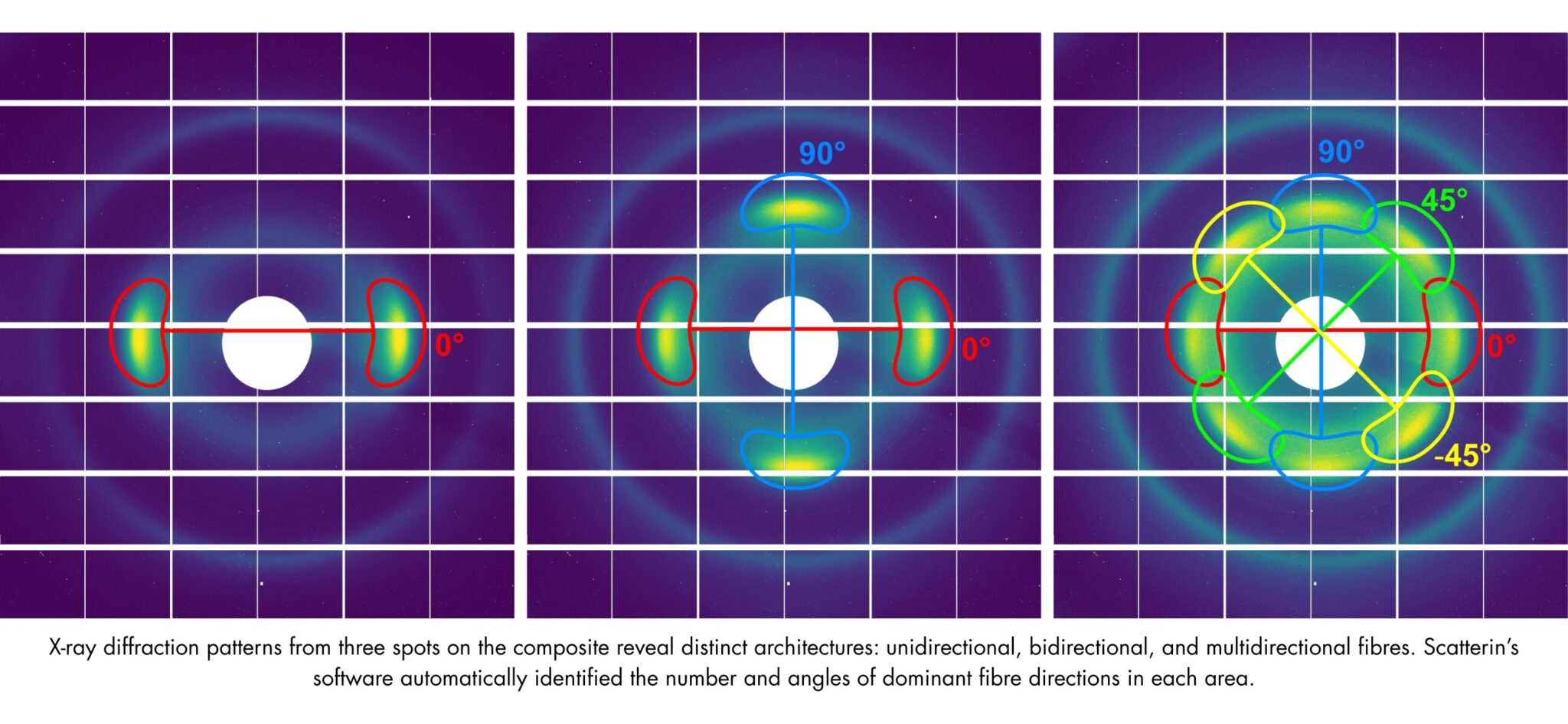

Scatterin achieved proof of concept that measurements of carbon-fibre reinforced polymers (CFRPs), processed through the company’s proprietary data analysis software, can reveal the orientation of individual fibres in semi-crystalline materials. The company’s algorithms, already validated on metals, have now been shown to be effective on CFRPs.

At DanMAX, the PXRD (Powder X-ray Diffraction) instrument provided a focused, size-tunable beam and a rapid sweep-mode stage that captured complete diffraction patterns from every angle within minutes.

“With these experiments at MAX IV, we could map real components very quickly. We can then visualise which fibre orientation we have at which part of the component.”

Ahmet Bahadır Yıldız · CEO

Fast-tracking industrial innovation

With this proof of concept in hand, Scatterin is now looking ahead to industrial applications in technologies ranging from aircraft to wind turbines.

“This can increase innovation capacity, cut research and development cycles, and provide a powerful quality-control tool for industry,” Yıldız adds.

The RISE Department of Polymer, Fibres and Composites produced the reference components for the measurements. Part of this work was funded by the SMF Flyg programme under the National Aeronautical Research Programme (NFFP), Innovair, with joint funding from Vinnova and the Swedish Armed Forces.