Unlocking the potential of synchrotron X-ray and neutron facilities for industrial advancement

Our approach helps companies to streamline R&D processes and quality control measures, resulting in significant time and cost savings. By accessing previously unattainable information, our clients boost their capacity for innovation and competitiveness within their industries.

Partnership with Europe’s top synchrotron and neutron facilities enables dedicated Scatterin access windows to beamlines.

Our metallurgists, beamline scientists, and data engineers have led materials, process, and component development projects with global industrial leaders.

All data is analysed with our own software enabling complete data control and rapid analysis. We deliver action-ready results that link experiments with engineering decisions.

Services and Deliverables

Each project includes everything from planning and data collection to analysis and reporting — all managed by Scatterin team for full confidentiality and fast results.

Residual strain analysis

Measure residual strain and stress gradients in industrial components using synchrotron and neutron diffraction, with micrometer-level resolution and centimeter-level penetration.

- Only techniques enabling non-destructive 3D mapping of residual stress gradients.

- Penetration up to 7 cm in steel.

- Measurements in tri-axial residual stress condition.

- µm-level resolution can be reached in mapping.

Phase & precipitate analysis

Identify and quantify phases such as retained austenite and nanoscale precipitates using diffraction and small-angle scattering, achieving detection limits below 1 vol %.

- In-situ measurements in mimicked processing and service conditions with <1 second time resolution can be performed.

- Minority phases and precipitates (<1 vol%) can be detected.

- µm-level resolution can be reached in structural mapping.

In-situ analysis

Monitor phase transformations, defect evolution, and stress partitioning in real time during heating, deformation, or simulated service conditions.

- In-situ measurements during deformation or cycle within a large temperature range with <1 second time resolution can be performed.

- µm-level resolution in structural mapping.

Imaging & tomography

Dynamics of processes and movements in working equipment can be imaged and quantified in-real time with time resolution better than 1 ms by neutron and synchrotron X-ray radiography. Defects and other features inside materials can be reconstructed and quantified with resolution better than 1 µm.

Process & service condition simulation

- Quenching and partitioning dilatometer

- High-temperature and cryofurnaces

- Electro-Thermal Mechanical Testing System

- Deformation rigs for wide temperature range

- Various reaction chambers and electrochemical cells

Custom equipment & large components

If your requirements extend beyond the capabilities of existing sample environments and equipment at neutron and synchrotron X-ray facilities, we facilitate the arrangement of necessary technical and safety provisions. Whether it involves integrating your proprietary equipment—such as furnaces, battery cells, or specialized working parts like engines—or enhancing the existing setup, we ensure seamless coordination. Our experience includes adeptly navigating and complying with the stringent technical and safety regulations governing neutron and synchrotron facilities.

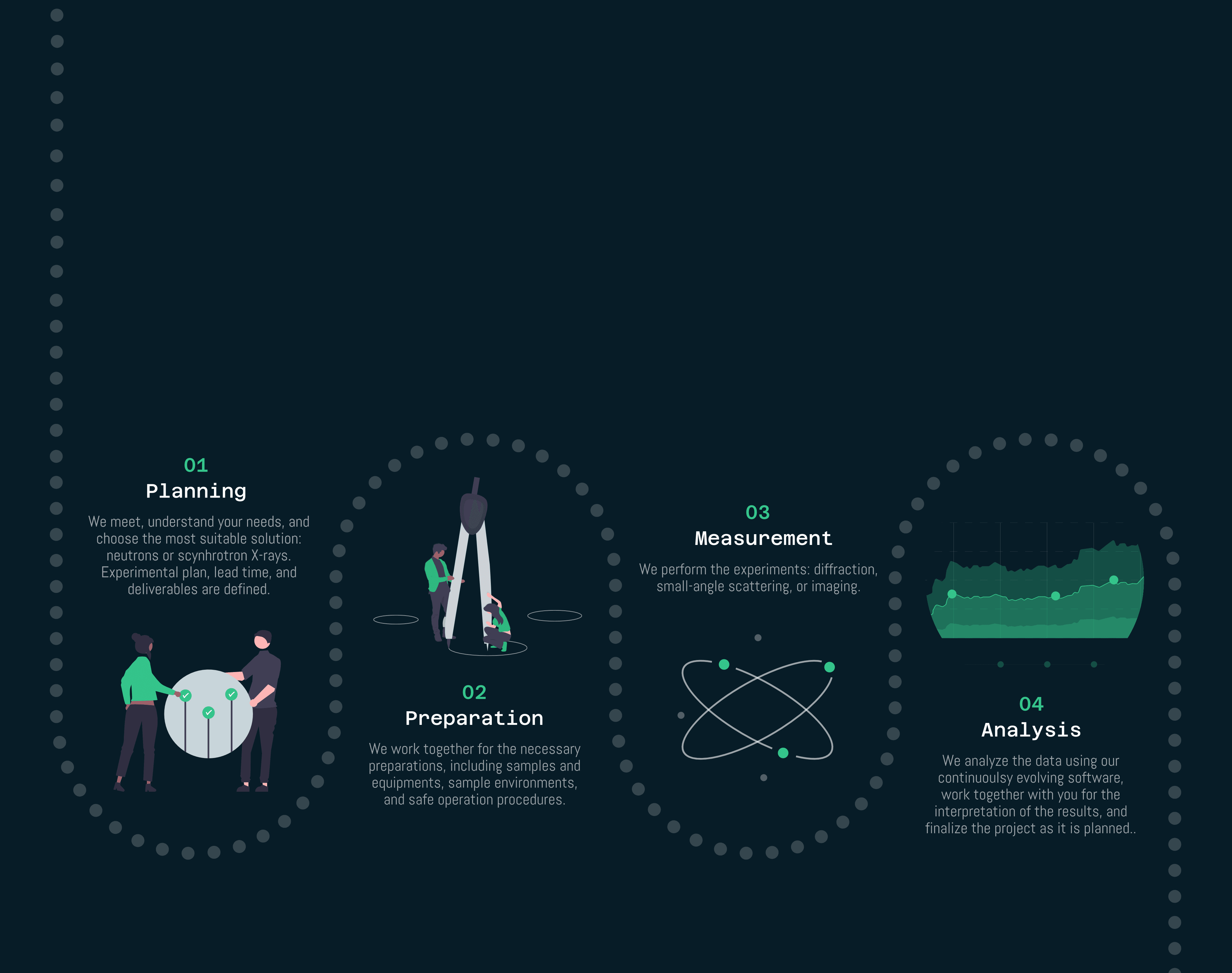

From materials challenges to business value — in four orchestrated steps.

Scatterin manages the entire workflow: from experiment planning to decision-ready results. All data and results are fully confidential and delivered within 1–2 weeks after beamtime. Your material, your data, your IP.

Define objectives, scope and deliverables together with your team, ensuring every project addresses your need.

Preparation of samples and experimental design, guaranteeing compatibility, precision.

Perform synchrotron and neutron measurements: diffraction and small-angle scattering.

Data analysis with our own software. Result delivery in 1-2 weeks: industry leading turnaround time.

Scatterin - Your go-to partner for advanced materials analysis

Tell us about your challenge. We will handle everything from experiment design to analysis.